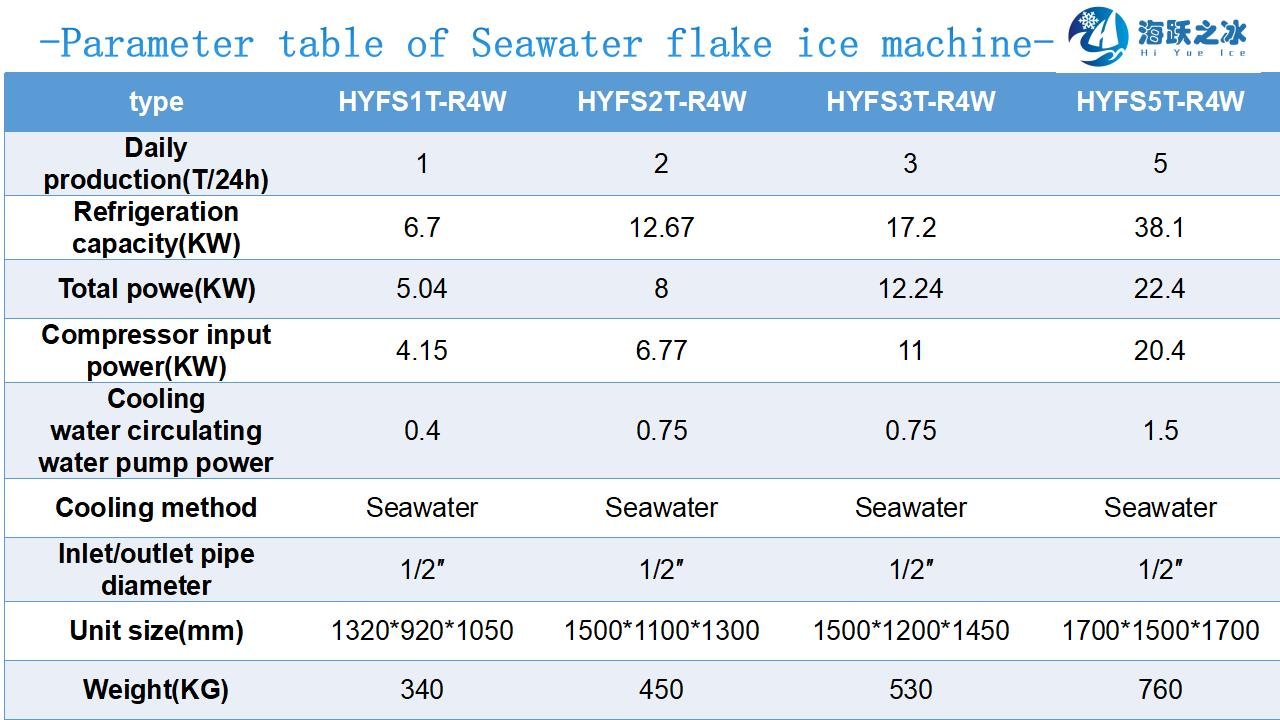

Brand: Haiyue Product origin: Qingdao China

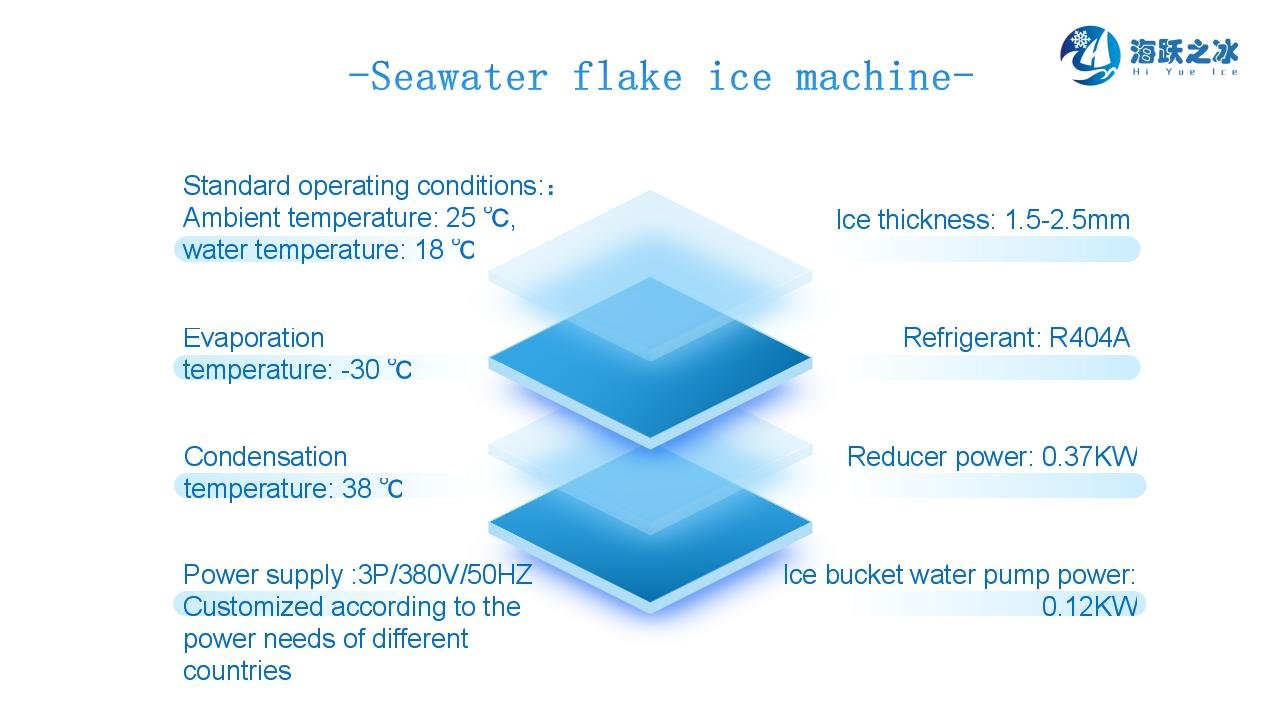

A seawater flake ice machine is a specialized industrial refrigeration system designed to produce flake ice directly from seawater. This technology is crucial for industries that operate in marine environments and require a readily available and efficient cooling medium.

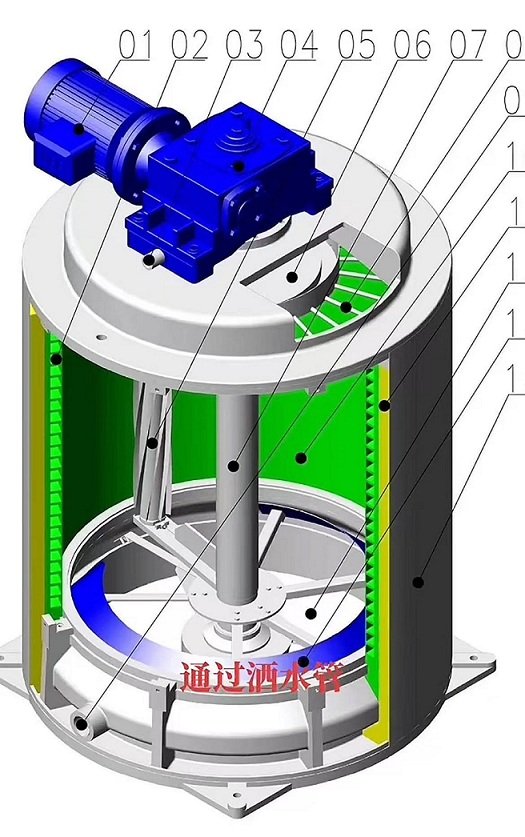

• Ice making system: It includes evaporator,reducer, water pump,upper and lower basement and other matching accessories.The material of the most components is SUS304,316, so the quality is very high and it is very reliable.

• Refrigeration system: It includes compressor, condenser, reservoir,pressure switches and other matching accessories. All the parts we use are famous brand so we can make sure the quality.For the compressor, we usually use Bitzer, Copeland, Refcomp, Emerson and so on.

• Controling system: It includes PLC controlling box, A/C contactor. thermal relay,air switch, touch screen and other matching accessories. All the components are famous brand and high quality.

Standard power supply for large capacity tube ice making machine is 3P/ 380V/50HZ, also we can customize it for you.