Flake Ice Machine: A Comprehensive Introduction

1. What is a Flake Ice Machine?

A flake ice machine is an industrial refrigeration system designed to produce a continuous supply of flake ice. This type of ice is characterized by its thin, flat, dry, and malleable properties. Unlike cube or nugget ice, flake ice has a low temperature (typically around -7°C / 19°F) and a large surface area, making it one of the most efficient forms of ice for cooling applications.

2. How Does It Work?

The working principle involves a simple yet effective process:

1. Water Supply: A water pump circulates water from a reservoir.

2. Freezing Surface: The water is sprayed onto the inner surface of a vertically or horizontally oriented cylindrical evaporator/drum, which is chilled to extremely low temperatures.

3. Ice Formation: A thin layer of ice freezes onto the drum's surface.

4. Harvesting: As the drum rotates, a helical cutter (or "auger") scrapes the thin layer of ice off the surface.

5. Discharge: The scraped ice is pushed through the machine and discharged into a storage bin. The process is continuous, ensuring a steady supply of ice.

3. Key Characteristics of the components:

· Compress: We use famous compressor for the ice machine, such as Bitzer, Refcomp, Copeland,Danfoss and so on.the performance, efficiency, and reliability of the compressor directly determine the ice-making capacity, speed, and energy consumption of the entire ice maker.

· Evaporator: The material of our evaporator is SUS304 insulating polyurethane foam. The main function of the evaporator is to absorb heat from water flowing over its surface. The refrigerant circulating inside the evaporator tubes evaporates (boils) at a very low temperature, absorbing a large amount of latent heat from the water, which then freezes on the cold surface. Without a good quality evaporator, the machine cannot produce ice or the ice is not good.

. For the ice blade and bearings, we also use material of SUS304. Other components: For all the components, we use famous brand to make sure the quality is perfect. We are manufacturer, so we value the quality very much.

.For the controlling system, we use PLC controlling system. In modern ice makers, the Programmable Logic Controller (PLC) acts as the intelligent brain of the entire machine. It is a ruggedized industrial computer that automates operations, optimizes performance, and ensures reliability. Replacing older mechanical timers and relays, the PLC provides sophisticated, precise, and flexible control.

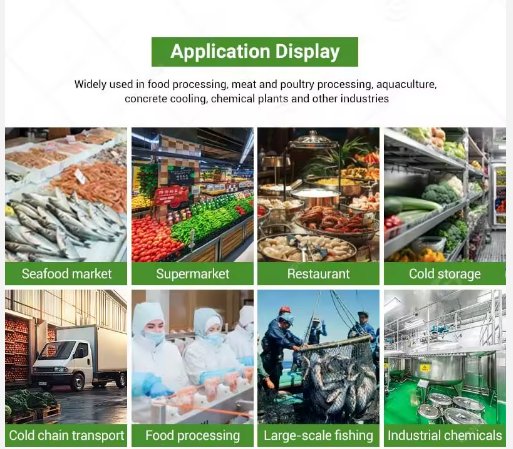

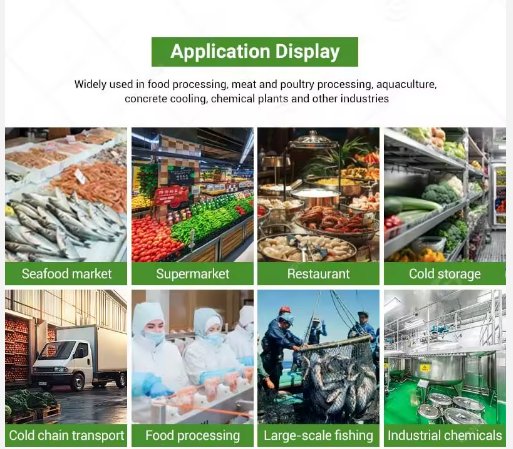

4.Common Applications

Flake ice machines are incredibly versatile and are used across numerous industries:

· Food & Beverage:

· Display and preservation of seafood, meat, and poultry in supermarkets.

· Chilling vegetables and fruits during processing and transportation (e.g., salad production).

· Mixing directly with dough or food ingredients for temperature control.

· Fishing & Aquaculture:

· Preserving the catch on fishing boats by creating an ice-water slurry that minimizes physical damage.

· Oxygenation and temperature control in fish transport tanks.

· Construction:

· Cooling concrete mixes during large pours to prevent cracking and control the heat of hydration.

· Chemical & Pharmaceutical:

· Temperature control for chemical reactions and processes in laboratories and plants.

· Healthcare:

· Used in therapeutic ice packs due to its moldability and softness.