Flake Ice Machine Introduction:

1.What is a Flake Ice Machine?

A flake ice machine is an industrial refrigeration system designed to produce a continuous supply of flake ice. This type of ice is characterized by its thin, flat, dry, and malleable properties. Unlike cube or nugget ice, flake ice has a low temperature (typically around -7°C / 19°F) and a large surface area, making it one of the most efficient forms of ice for cooling applications.

2. How Does It Work?

The working principle involves a simple yet effective process:

1. Water Supply: A water pump circulates water from a reservoir.

2. Freezing Surface: The water is sprayed onto the inner surface of a vertically or horizontally oriented cylindrical evaporator/drum, which is chilled to extremely low temperatures.

3. Ice Formation: A thin layer of ice freezes onto the drum's surface.

4. Harvesting: As the drum rotates, a helical cutter (or "auger") scrapes the thin layer of ice off the surface.

5. Discharge: The scraped ice is pushed through the machine and discharged into a storage bin. The process is continuous, ensuring a steady supply of ice.

3. Key Characteristics of Flake Ice

· Shape: Thin, flat flakes.

· Temperature: Approximately -5°C to -7°C (23°F to 19°F).

· Texture: Soft, dry, and pliable.

· Surface Area: High surface-area-to-volume ratio.

4. Major Advantages (Key Benefits)

· Superior Cooling Efficiency: The high surface area allows flake ice to absorb heat rapidly, providing faster and more effective cooling than other ice types.

· Moldable and Gentle: Its soft texture makes it ideal for packing and cooling delicate products like seafood, poultry, and fresh produce without causing damage.

· Pumpable Slurry: When mixed with water, flake ice creates a slurry that can be pumped through pipes for precise cooling in industrial processes or fishing vessels.

· Excellent Contact: It easily conforms to the shape of products, ensuring intimate contact and uniform cooling.

· Cost-Effective: High energy efficiency and rapid production rates make it an economical choice for many high-volume applications.

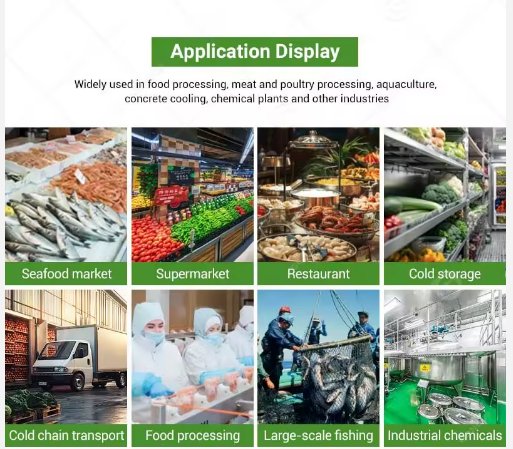

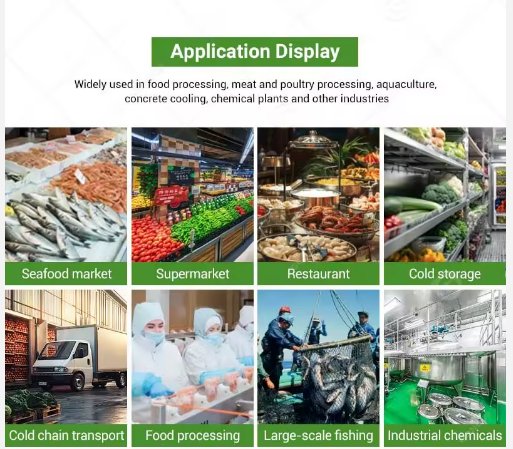

5. Common Applications

Flake ice machines are incredibly versatile and are used across numerous industries:

· Food & Beverage:

· Display and preservation of seafood, meat, and poultry in supermarkets.

· Chilling vegetables and fruits during processing and transportation (e.g., salad production).

· Mixing directly with dough or food ingredients for temperature control.

· Fishing & Aquaculture:

· Preserving the catch on fishing boats by creating an ice-water slurry that minimizes physical damage.

· Oxygenation and temperature control in fish transport tanks.

· Construction:

· Cooling concrete mixes during large pours to prevent cracking and control the heat of hydration.

· Chemical & Pharmaceutical:

· Temperature control for chemical reactions and processes in laboratories and plants.

· Healthcare:

· Used in therapeutic ice packs due to its moldability and softness.

6. Why Choose a Flake Ice Machine?

In summary, a flake ice machine is the ideal solution when your primary need is for rapid, efficient, and gentle cooling. Its unique product—flake ice—offers unmatched versatility for applications ranging from food presentation to large-scale industrial processes. When reliability, efficiency, and product quality are paramount, a flake ice machine is an excellent investment.